In recent years, there have been feedbacks from customers that the peeling force of various manufacturers is always inconsistent with the test results of light release force, and some data are always smaller than others. Now I will objectively analyze the specific reasons for you. ! The following will analyze the common peel force testing machine manufacturers on the market from several dimensions.

1. In terms of mechanical structure 1. It basically adopts ordinary ball screw drive, which is more mature and is a standard part; 2. It adopts servo motor or stepper drive, servo motor and stepper motor, servo and stepper motor are both Pulse control, the difference is in the speed, the servo speed is 3000 rpm, the step is 600 rpm, the torque is similar, and other parameters are the same, which has almost no effect on the data of the machine, and the price difference is about 1,000 yuan; 3. Synchronous wheel , Synchronous belt drive, there will be some influence here. The type and machining accuracy of the synchronous wheel will affect the displacement accuracy, but have little effect on the test force value; 4. The bearings will be made of domestic or Japanese brands, and they are all produced in China. More mature, less impact; From the above, we can see that the mechanical structure has little impact on the test value, because there are mature supply chains in the market, plus the assembly experience of tension machine manufacturers for many years, the above can be basically excluded.

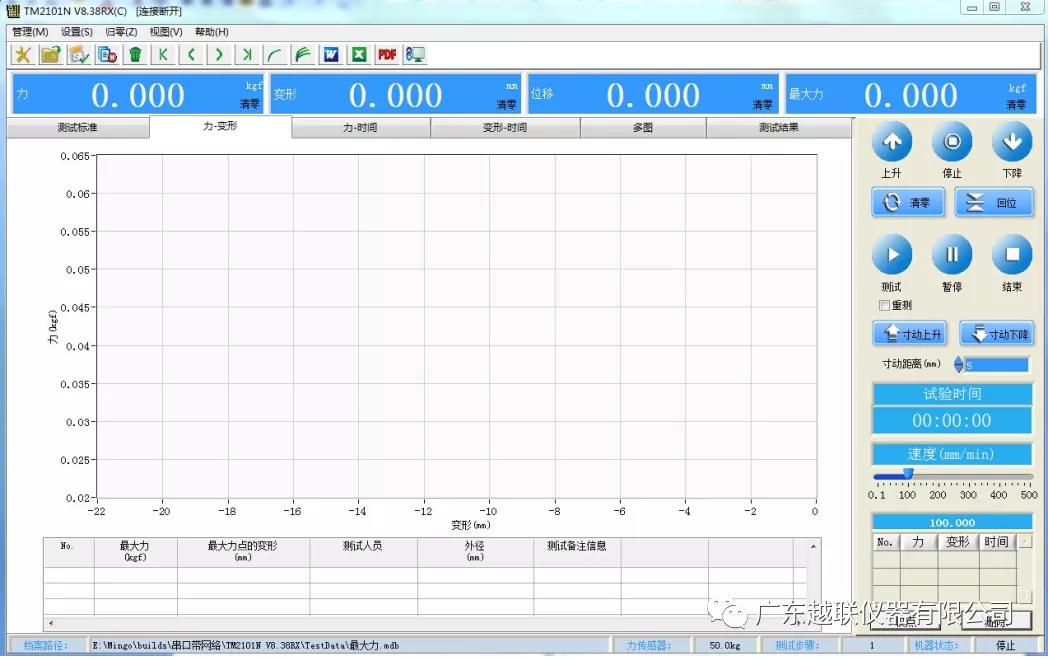

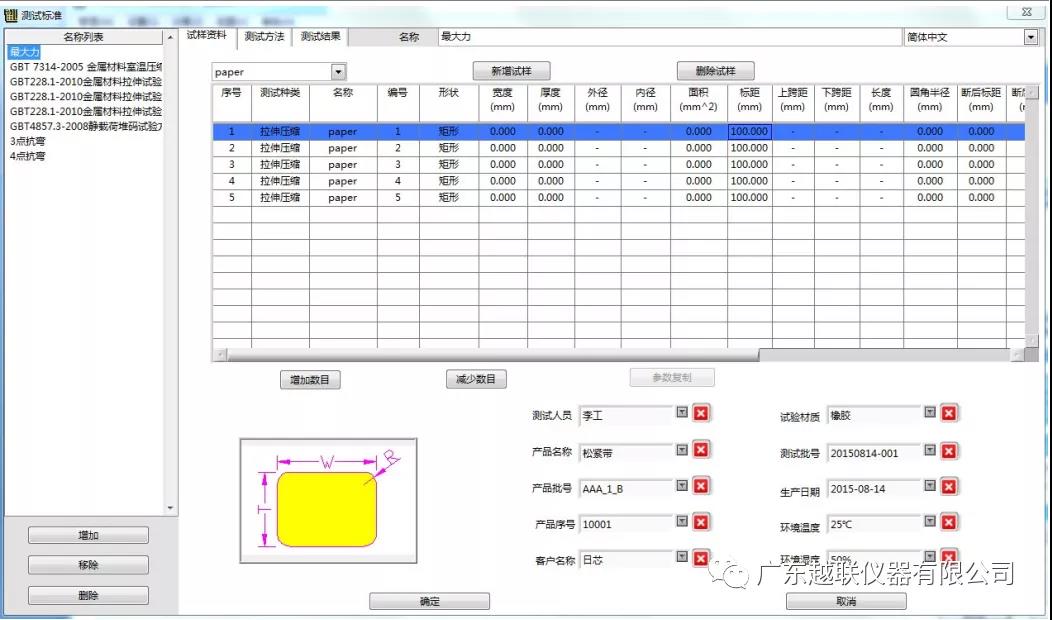

2. Most of the popular peeling force test software in the test software market are provided by the same company software company, the model is TM2101N. The tensile machine manufacturer will ask the software company to help design a different layout. settings are the same.

Therefore, the data deviation caused by the software can also be excluded!

3. Sensors There are currently 5 sensors from different brands and manufacturers in the mainstream market for comparison! 1. The minimum capacity of Japanese NTS is 10N, and the accuracy is 0.03%. If a 10N sensor is used, the accuracy is 0.3G, and the purchase price is about 13,000 yuan; 2. The minimum capacity of Taiwan NTS is 10N, and the accuracy is 0.03%. If a 10N sensor is used, the accuracy It is 0.3G, and the purchase is about 5,500 yuan; 3. The minimum capacity of Jiangsu-made American transmission is 5N, and some models can achieve an accuracy of 0.03%. If a 10N sensor is used, the accuracy is 0.15G, and the bulk purchase is about 800 yuan;

4、天津产美国世铨传感器 最小容量50N,部分型号可到精度是0.05%,如果使用50N的传感器,精度是2.5G,批量进货约800元人民币,所说已将工厂转移到印度; 5、浙江柯力代工美国SUNCELLS 最小容量50N,精度是0.05%,如果使用50N的传感器,精度是2.5G,单个进货价约250元人民币; 目前SUNCELLS这款称重传感器是市面上剥离力试验机见得较多的,这款传感器在最下面一行拼音可以看出是宁波柯力传感器公司生产的,但在SunCells商标的下面,激光打上的却是MK SOLUTIONIX(USA)LTD,说明是美国的公司;从MK SOLUTIONIX(USA)LTD的字体可以看出,像是后面激光补打上去的,可以看出是美国这家公司是委托浙江柯力代工的,因为美国公司在中国如果没有CMC认证是不具备生产称重传感器资质的。 上面这款5KG的传感器广泛应用在0~100g力的轻离型力剥离力测试机台上,按照上面的0.05%精度,我们可以算出5KG=5000G*0.05%=2.5G 得出这个传感器的精度是2.5克;在超轻离型力的表现中应略差,可能会造成部份数据略为偏大的可能,且线性和重复精度有待验证。 此款传感器价格低廉,在淘宝、抖音都可买到,也可直接找宁波柯力厂家买,价格也差不多。主要应用于称重行业;

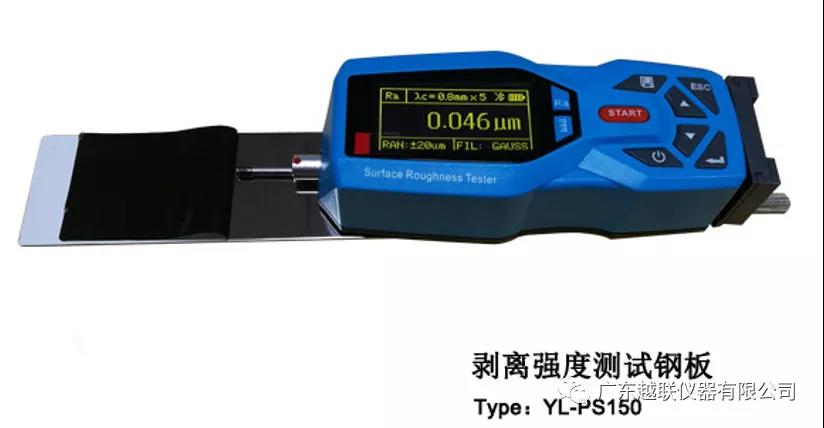

四、剥离钢板 1、新的国标要求不锈钢板粗糙度为50±25nm,这个范围有些大,也就是说25nm~75nm都可满足,但在轻离型的测试中却有很大的区别,在100G以上的测试结果中影响不是太大,目前能满足此粗糙度条件的不锈钢剥离钢板的大约有三家,一家是美国的cheminstruments,另外两家厂商均在东莞,且成立的时间都在15年上下。 2、美国Cheminstruments剥离钢板在人民币150元左右,YL钢板在60元左右(粗糙度46~48nm),另一家厂商售价在80~180元不等(粗糙度42~43nm);

5. Conclusion Analysis According to the above analysis, in the case of ensuring that the assembly technology of each manufacturer is qualified and the test methods are consistent, it is only necessary to select sensors of the same type and model from the same manufacturer and purchase steel plates with the same roughness to solve this problem. of! So whether to test according to the national standard or to use a certain manufacturer as the standard, this is a question to be considered! If the selection of the main parts of the machine provided by a certain manufacturer is wrong, should the entire adhesive market be catered for? If the batches of the steel plates of a certain manufacturer are different each time and the roughness is also different, what should be done when the test results deviate? Do you acquiesce and accept? The above is only my personal opinion! Hope you all correct me! (If you need to communicate with Yuelian Instrument, please contact the author)